GEMFG Electric Tricycle Lithium Batteries: Powering the Future of Sustainable Urban and Rural Mobility

Date: 2020-08-01 Categories: Articles Hits: 839

Within the rapidly evolving landscape of personal and commercial transportation, electric tricycles have emerged as indispensable electric vehicles (EVs) for urban deliveries, passenger transport, and rural mobility solutions. At the core of these versatile EVs lies their critical power supply: the battery. The shift toward advanced lithium battery technology represents a transformative leap in efficiency and sustainability, positioning GEMFG as an industry pioneer with its cutting-edge Tricycle Lithium Batteries engineered to deliver unparalleled endurance, reliability, and operational economy. This essential energy storage component serves as the lifeblood of modern tricycles, directly determining travel range, payload capacity, total cost of ownership, and overall service viability. Selecting a high-performance lithium battery is fundamental to unlocking the full potential of three-wheeled electric vehicles, ensuring dependable operation whether navigating crowded city streets, traversing rural pathways, or transporting heavy commercial payloads.

Electric tricycles fulfill diverse roles – from last-mile delivery vehicles and passenger rickshaws to mobile vending platforms and disability mobility aids. These applications demand a power supply that combines robust performance with exceptional practicality. Operators depend on their tricycles for daily income generation, requiring extended operational hours under varying environmental stresses. Substandard battery systems compromise range under load, necessitate frequent mid-shift recharging, and accelerate performance degradation – directly impacting livelihood sustainability. Consequently, the lithium battery functioning as the primary power source must satisfy rigorous operational criteria: exceptional energy density for maximum range with heavy payloads, unwavering reliability across temperature extremes and vibration-intensive environments, rapid recharge capability to minimize revenue-disrupting downtime, extended cycle life for reduced replacement frequency, and comprehensively integrated safety mechanisms to protect operators, passengers, and goods. GEMFG’s specialized Tricycle Lithium Batteries are precision-engineered to exceed these critical benchmarks, establishing a new standard for electric vehicle power supply in the global three-wheeler market.

Unrivaled Energy Density for Enhanced Payload and Range

GEMFG Tricycle Lithium Batteries utilize next-generation lithium-ion chemistry, structural cell optimization, and proprietary energy storage management systems to achieve industry-leading volumetric and gravimetric energy density. This foundational technological superiority translates directly into significantly extended operational range per charge cycle compared to obsolete lead-acid or nickel-based battery systems. Operators can confidently undertake longer delivery routes, complete multiple passenger transit shifts, or conduct full-day commercial activities without anxiety over premature power depletion. Advanced electrode formulations and minimized internal resistance dramatically reduce parasitic energy losses during standby periods, ensuring optimal charge retention during overnight storage or intermittent usage patterns. Whether powering cargo tricycles carrying 500kg loads through urban centers, passenger variants navigating hilly terrain, or specialized utility models in agricultural settings, GEMFG lithium batteries deliver sustained high-current power supply capabilities essential for maintaining momentum under demanding real-world conditions.

Engineered Robustness for Demanding Operating Environments

Electric tricycles operate in some of the most challenging environments – exposed to monsoonal rains, desert dust, unpaved road vibrations, and temperature fluctuations from -30°C to 60°C. The power supply must demonstrate exceptional resilience against these cumulative stresses. GEMFG Tricycle Lithium Batteries incorporate military-grade protective engineering: impact-resistant alloy casings, multi-layered IP67-rated sealing against particulate and liquid ingress, and vibration-dampening internal architectures. These lithium batteries withstand continuous mechanical shock from potholed roads, resist corrosion in high-humidity coastal regions, and maintain integrity when subjected to frequent loading/unloading cycles. Integrated active thermal management systems and temperature-tolerant electrolytes ensure stable electrochemical performance whether operating in tropical heat or sub-zero winters. This engineered durability directly reduces maintenance interventions and extends battery service life – critical factors for commercial operators where vehicle availability directly impacts profitability.

Ultra-Fast Recharging for Continuous Fleet Utilization

In commercial tricycle operations, charging downtime equates to lost revenue opportunities. GEMFG integrates intelligent rapid-recharge technology within its Tricycle Lithium Batteries, featuring adaptive charging algorithms governed by multi-core Battery Management Systems (BMS). These lithium batteries dynamically modulate incoming current and voltage based on real-time cell temperature, state-of-charge, and historical usage patterns. This enables 2-3X faster recharge cycles versus conventional alternatives – achieving 95% capacity in under two hours using appropriate charging infrastructure. Operators benefit from lunch-break recharging capability, overnight fleet replenishment without requiring extended charging windows, and opportunity charging during scheduled breaks. The combination of high energy storage density and rapid energy replenishment establishes unprecedented vehicle availability rates, maximizing daily revenue potential for delivery services, transport cooperatives, and logistics enterprises reliant on three-wheeler fleets.

Extended Service Life for Superior Economic Value

The economic calculus for commercial tricycles demands battery solutions delivering minimum 3-5 year service lives under daily deep-cycle conditions. GEMFG Tricycle Lithium Batteries are engineered for 2000+ complete charge-discharge cycles while maintaining >80% original capacity – outperforming lead-acid alternatives by 400-600%. This longevity stems from patented cathode stabilization technology, lithium deposition prevention mechanisms, and continuous cell-balancing during both charging and discharging phases. Combined with zero routine maintenance (no water refilling, terminal cleaning, or equalization charges), the total cost of ownership plummets by 60-70% over the operational lifespan. For fleet managers, this translates into predictable battery replacement schedules, reduced capital expenditure volatility, and enhanced profitability through minimized vehicle downtime and maintenance labor costs.

Multi-Tiered Safety Architecture for Public Road Compliance

Public roadway operation imposes stringent safety obligations absent in closed-campus vehicles. GEMFG embeds a comprehensive safety ecosystem within its Tricycle Lithium Batteries:

Cell-Level Voltage Monitoring with Active Balancing: Prevents individual cell overvoltage during regenerative braking and undervoltage during hill climbs

Dynamic Current Limiting: Automatically restricts discharge current during acceleration overloads and charge current during voltage surges

Multi-Sensor Thermal Regulation: Initiates cooling protocols before critical temperatures are reached

Vibration-Immune Connection Systems: Prevents arc faults from connector fatigue

Automotive-Grade Battery Management Systems: Compliant with ISO 26262 functional safety standards

Fire-Containment Cell Separation: Ceramic separators and flame-retardant electrolytes suppress thermal propagation

The battery enclosure exceeds UN38.3 transportation safety requirements and incorporates crash-absorbing structural elements – critical for protecting occupants in three-wheeled vehicles with inherently different dynamics than four-wheeled EVs.

Transformative Applications Across Mobility Ecosystems

GEMFG lithium batteries enable revolutionary performance across diverse tricycle applications:

Urban Logistics: Empowering last-mile delivery tricycles with 120km+ daily range carrying 0.5-ton payloads

Passenger Transport: Enabling 14-hour continuous operation for electric rickshaws in megacity transit networks

Mobile Commerce: Providing stable power for refrigeration units in food-vending tricycles

Agricultural Support: Delivering torque-rich performance for farm-to-market transport on unpaved roads

Disability Mobility: Offering reliable hill-climbing capability for motorized assistive tricycles

The dramatic weight reduction (60% lighter than equivalent lead-acid packs) significantly enhances vehicle dynamics: improving hill-climb performance by 40%, reducing braking distances, and enabling payload capacity increases up to 30%. These performance advantages directly translate into economic benefits for commercial operators and accessibility improvements for personal mobility users.

Uncompromising Manufacturing Excellence and Global Support

GEMFG’s Tricycle Lithium Batteries are produced under IATF 16949 automotive quality management systems, incorporating automated optical inspection, robotic assembly, and 72-hour validation testing. Each battery undergoes real-world simulation cycling, thermal shock testing, and ingress protection validation before shipment. This manufacturing rigor ensures compatibility with major motor controllers and charging systems across global markets. Supporting this technical excellence, GEMFG provides application-specific power supply integration guides, regional service center networks, and remote diagnostics via integrated telematics – enabling proactive maintenance and minimizing operational disruptions for fleet operators worldwide.

Conclusion: The Advanced Power Core for Three-Wheeled Electrification

GEMFG Tricycle Lithium Batteries represent the technological apex in electric vehicle power supply solutions, specifically engineered for the unique demands of three-wheeled transportation. By delivering class-leading energy density for maximum operational range, vibration-resistant construction for real-world durability, ultra-rapid recharging for continuous revenue generation, extended cycle life for reduced operating costs, and comprehensive safety integration for public road compliance, these lithium batteries are redefining the economic and functional parameters of tricycle mobility. As global cities implement zero-emission transport policies and emerging economies electrify their paratransit networks, GEMFG provides the sophisticated energy storage technology enabling sustainable, profitable, and reliable tricycle operations across the commercial and personal mobility spectrum. This represents not merely a battery advancement, but the foundation for transforming urban logistics and rural transportation ecosystems through electrified three-wheeled solutions.

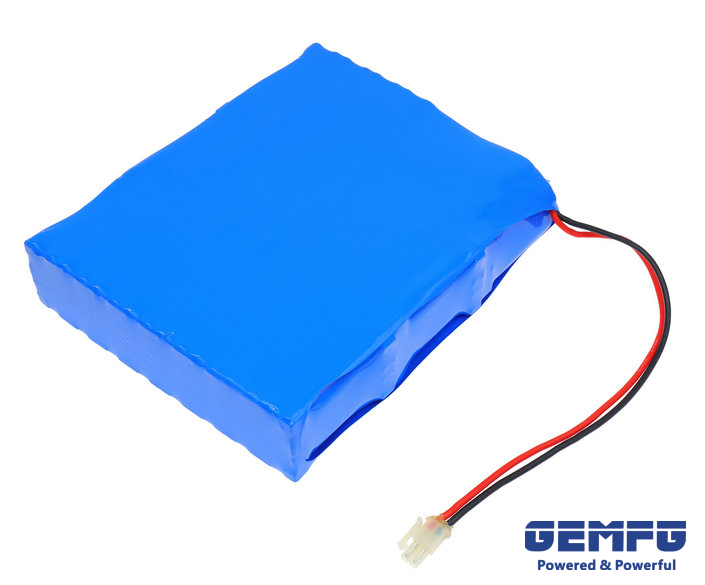

GiB 36-12EB

GiB 36-12EB  GiB 36-10.4EB

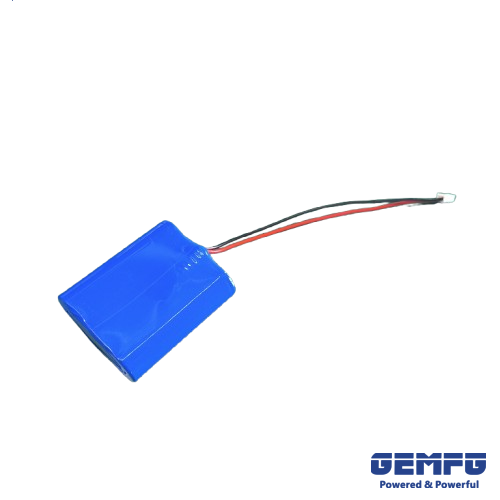

GiB 36-10.4EB  GiB 36-10.4EB

GiB 36-10.4EB  GiB 60-50GC

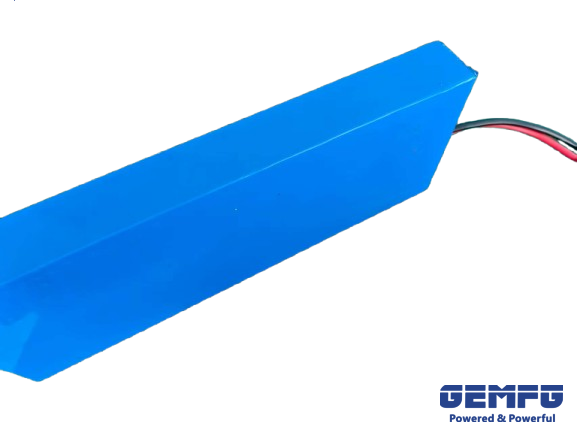

GiB 60-50GC  GiB 48-150GC

GiB 48-150GC  GiB 12-200

GiB 12-200  GiB 12-50

GiB 12-50  GiB 12-100

GiB 12-100  GiB 51R200

GiB 51R200  GiB 51R150

GiB 51R150  GiB 46.8-20EB

GiB 46.8-20EB  GiB 24-100

GiB 24-100  GiB 24-200

GiB 24-200  GiB 12-20MS

GiB 12-20MS  GiB 12-4MS

GiB 12-4MS  GiB 18-5.4DE

GiB 18-5.4DE  GiB 14.4-6.7OC

GiB 14.4-6.7OC  GiB 25.9-15XM

GiB 25.9-15XM  GiB 3.7-1.6HPC

GiB 3.7-1.6HPC  GiB 7.2-2.1SP

GiB 7.2-2.1SP  GiB 3.7-2.2SL

GiB 3.7-2.2SL  GiB 25.9-13SL

GiB 25.9-13SL  GiB 7.4-5.2EL

GiB 7.4-5.2EL  GiB 7.4-10SL

GiB 7.4-10SL  GiB 22.8-22FPV

GiB 22.8-22FPV  GiB 22.2-30FPV

GiB 22.2-30FPV  GiB 22.2-12FPV

GiB 22.2-12FPV  GiB 22.8-5FPV

GiB 22.8-5FPV  GiB 22.8-8FPV

GiB 22.8-8FPV  GiB 12-12SB

GiB 12-12SB  GiB 3.7-7.8RB

GiB 3.7-7.8RB  GiB 12-12SB

GiB 12-12SB  GiB 14.8-18RB

GiB 14.8-18RB  GiB 3.7-10PB

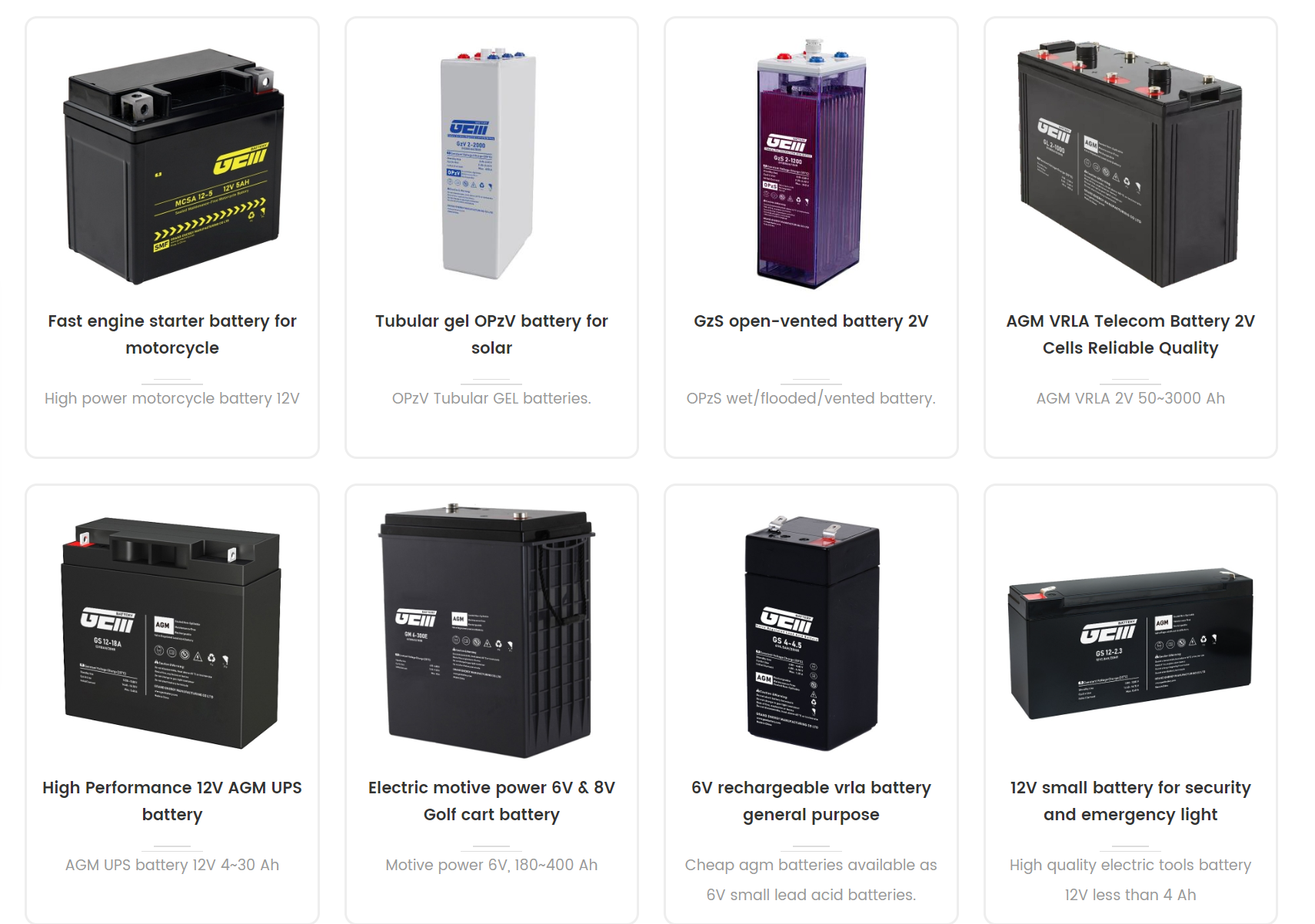

GiB 3.7-10PB  Lead-acid Battery | OPzV & OPz...

Lead-acid Battery | OPzV & OPz...