GEMFG AGV Lithium Batteries: Powering Unprecedented Efficiency in Automated Logistics

Date: 2020-06-06 Categories: Articles Hits: 696

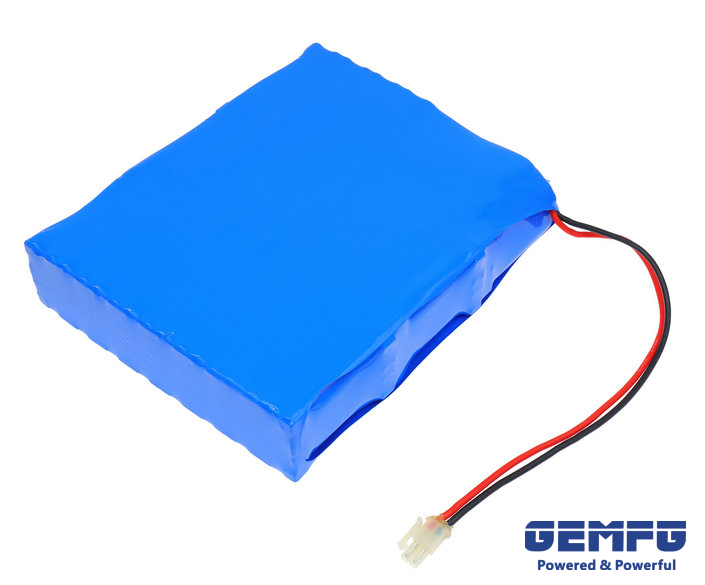

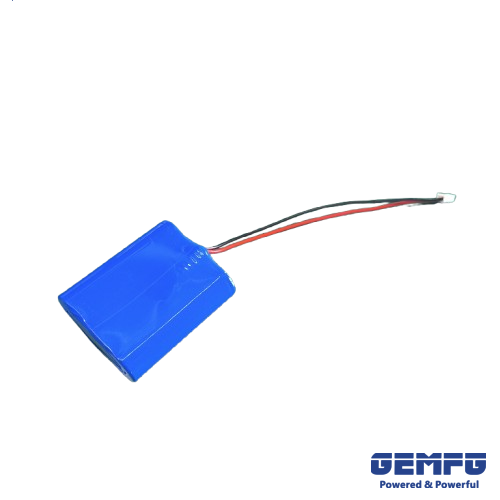

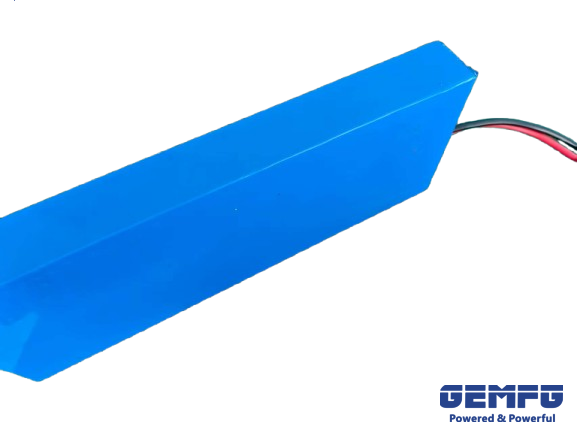

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) now revolutionize industrial operations, delivering unmatched efficiency, precision and cost-effectiveness across modern logistics systems. At the very core of these sophisticated material handling systems lies their critical power supply: the battery. The evolution towards high-performance lithium battery technology represents a fundamental advancement, and GEMFG stands at the vanguard, delivering exceptional AGV Lithium Batteries engineered specifically to meet the rigorous demands of continuous, automated operations. This essential power supply component is the lifeblood of the AGV or AMR, directly dictating uptime, throughput, operational cost, and the overall reliability of the logistics workflow. Selecting an optimal lithium battery is paramount for maximizing the return on investment in automation, ensuring seamless 24/7 operation, and unlocking the full potential of modern logistics and warehouse management systems.

AGVs and AMRs operate in demanding environments, often requiring non-stop functionality across extended shifts or even continuous operation. Their power supply must be exceptionally robust, reliable, and capable of sustaining high energy demands without interruption. Any failure or inefficiency in the battery system can lead to costly downtime, disrupted workflows, delayed shipments, and compromised overall logistics efficiency. Therefore, the lithium battery serving as the primary power supply for these automated workhorses must satisfy stringent industrial criteria. It demands exceptional energy density to maximize runtime and minimize required charging pauses, unwavering stability and reliability under heavy cyclic loads and varying ambient temperatures, rapid recharging capabilities to enable high utilization rates (including opportunity charging), advanced intelligence for fleet management, and, critically, absolute safety integrated into every aspect of its design to protect personnel, equipment, and inventory. GEMFG's dedicated AGV Lithium Batteries are meticulously engineered to excel across all these critical dimensions, establishing a new benchmark for power supply in industrial automation and logistics.

Superior Energy Density for Maximized Operational Uptime

GEMFG AGV Lithium Batteries leverage cutting-edge lithium-ion chemistry, advanced cell architecture, and proprietary electrode formulations to achieve industry-leading energy density. This fundamental technological advantage translates directly into significantly extended operational runtimes per charge cycle compared to traditional lead-acid or older generation lithium battery solutions. AGVs and AMRs equipped with GEMFG batteries can cover greater distances, handle larger payloads over longer periods, and complete more tasks before requiring a recharge. This directly enhances throughput and reduces the frequency of charging interruptions. The sophisticated internal design minimizes energy loss through self-discharge, ensuring the battery retains its stored energy effectively during scheduled breaks or shift changes. Whether powering pallet transporters in vast distribution centers, unit-load handlers in manufacturing plants, or intricate assembly line feeders, GEMFG lithium batteries deliver the sustained, high-capacity power supply essential for maximizing the productivity and economic benefit of automated logistics fleets.

Engineered Resilience for Demanding Industrial Environments

Industrial settings, warehouses, and manufacturing floors present unique challenges: fluctuating temperatures, dust, vibrations, and sometimes humidity. The power supply for AGVs and AMRs must be built to endure these conditions reliably. GEMFG AGV Lithium Batteries are constructed with exceptional environmental and mechanical robustness. Utilizing high-strength casing materials engineered for impact resistance, advanced multi-stage sealing technologies proven against ingress (IP ratings suitable for industrial applications), and rigorous protection standards, these lithium batteries effectively withstand dust, moisture, vibration, and mechanical stress encountered daily in logistics operations. Furthermore, integrated sophisticated thermal management systems and carefully selected components grant these batteries outstanding tolerance to wide temperature ranges. Designed to perform consistently and safely in both high-temperature factory environments (up to 60°C / 140°F) and cold storage facilities (down to -30°C / -22°F), GEMFG batteries guarantee a stable and dependable power supply for the AGV/AMR's drive systems, navigation sensors, and control computers, irrespective of harsh ambient conditions. This unwavering reliability minimizes operational disruptions and maintenance costs.

High-Efficiency Charging for Optimal Fleet Utilization

In high-throughput logistics environments, downtime for charging represents lost productivity. GEMFG integrates advanced high-efficiency charging technology into its AGV Lithium Batteries, specifically designed to support fast charging and opportunity charging paradigms. Employing intelligent charging algorithms managed by an advanced Battery Management System (BMS), these lithium batteries dynamically optimize charging parameters (current, voltage) based on real-time state-of-charge, temperature, and battery health. This intelligent approach enables significantly faster recharge cycles compared to conventional technologies. AGVs and AMRs can quickly top up during short breaks, scheduled pauses, or even during brief idle moments at pick/drop stations, drastically increasing vehicle availability and overall fleet utilization. The rapid recharge capability is a cornerstone of efficient AGV/AMR operation, enabling near-continuous workflow and maximizing the return on automation investment within demanding logistics schedules.

Integrated Intelligence and Connectivity for Smart Logistics

Modern automated logistics relies on data-driven optimization. GEMFG AGV Lithium Batteries are not merely energy sources; they are intelligent components of the AGV/AMR ecosystem. Equipped with sophisticated BMS technology, these lithium batteries provide continuous, real-time monitoring of critical parameters including state-of-charge (SoC), state-of-health (SoH), voltage, current, temperature, and cycle count. This rich data stream is communicated via industry-standard protocols (e.g., CAN bus, Ethernet) to the AGV/AMR controller and often upwards to fleet management software (FMS) or warehouse management systems (WMS). This connectivity enables predictive maintenance alerts, optimized charging scheduling, accurate runtime prediction, proactive battery replacement planning, and comprehensive fleet energy management. The intelligent power supply becomes a vital data point for overall system health and operational efficiency within smart logistics networks.

Comprehensive Safety Architecture for Industrial Peace of Mind

Safety within industrial facilities, especially where AGVs and AMRs operate alongside personnel and valuable assets, is paramount. GEMFG prioritizes safety as the foundation of its AGV Lithium Battery design and manufacturing. These lithium batteries incorporate a multi-layered, hardware-based safety architecture governed by a highly capable BMS. This system performs continuous, real-time monitoring and active protection, including:

Cell-Level Voltage Monitoring and Balancing: Ensures uniform cell performance and prevents overvoltage/undervoltage conditions.

Precise Current Monitoring and Overcurrent Protection: Safeguards against excessive discharge or charge currents and short circuits.

Multi-Point Temperature Monitoring and Thermal Management: Prevents overheating and ensures operation within safe thermal limits.

Robust Overcharge and Over-discharge Protection: Prevents damage from exceeding voltage limits.

Isolation Monitoring (where applicable): Enhances electrical safety.

The battery enclosure is constructed from premium fire-retardant and impact-resistant materials, rigorously tested to comply with stringent international safety standards (e.g., UL, IEC, UN38.3). This holistic safety engineering approach effectively mitigates risks associated with thermal events, electrical faults, or mechanical damage, ensuring a safe power supply within busy industrial and logistics environments.

Enabling Diverse Automated Logistics Applications

The superior performance characteristics of GEMFG AGV Lithium Batteries make them the power supply solution of choice across a vast spectrum of automated material handling applications:

Warehousing and Distribution Centers: Powering pallet movers, order pickers, and tow tractors for efficient goods movement and sorting, enhancing logistics throughput.

Manufacturing Facilities: Providing reliable energy for assembly line feeders, component delivery AGVs, and raw material transporters, supporting just-in-time production.

E-commerce Fulfillment Centers: Enabling high-speed sortation AMRs and mobile robots for rapid order processing and packing.

Airport Baggage Handling: Ensuring dependable operation for baggage tugs and sorting systems.

Hospital Logistics: Powering automated carts for linen, waste, meals, and supplies.

Cold Chain Logistics: Maintaining performance in refrigerated and frozen storage environments.

The combination of long runtime, fast charging, robustness, intelligence, and safety ensures GEMFG lithium batteries enhance operational efficiency and reliability across the entire automated logistics value chain. Furthermore, the significant weight savings compared to lead-acid batteries allow AGVs and AMRs to carry larger payloads or operate more efficiently, directly impacting bottom-line performance.

Unwavering Commitment to Quality and Global Support

GEMFG's dedication to excellence permeates every stage of the AGV Lithium Battery lifecycle. Manufacturing adheres to the strictest international quality management systems (e.g., ISO 9001) and industry-specific standards. Rigorous processes govern raw material selection, precision manufacturing, comprehensive in-process testing, and final validation, guaranteeing each battery meets the highest benchmarks for performance, reliability, cycle life, and safety. Complementing this product excellence, GEMFG provides dedicated global customer support. This includes expert technical consultation for seamless AGV/AMR integration, detailed installation and commissioning guidance, comprehensive training resources, proactive maintenance recommendations, and responsive after-sales service. This ensures operators and integrators have the necessary support to maximize the performance, lifespan, and return on investment of their AGV Lithium Battery power supply systems worldwide.

Conclusion: The Intelligent Power Foundation for Automated Logistics

GEMFG AGV Lithium Batteries represent the forefront of power supply technology for the rapidly evolving world of automated material handling. By delivering superior energy density for maximum uptime, engineered resilience for harsh industrial environments, high-efficiency charging for optimal fleet utilization, integrated intelligence for smart logistics management, and rigorously engineered safety for operational peace of mind, these lithium batteries are redefining the capabilities of AGVs and AMRs. They provide the robust, reliable, and intelligent energy foundation essential for warehouses, factories, and distribution centers to achieve new levels of efficiency, productivity, and competitiveness. As automation continues to revolutionize global logistics, GEMFG stands as a trusted partner, providing the advanced lithium battery solutions that empower the seamless, uninterrupted flow of goods in the modern supply chain. Choose GEMFG for the power supply that drives the future of automated logistics forward

GiB 36-12EB

GiB 36-12EB  GiB 36-10.4EB

GiB 36-10.4EB  GiB 36-10.4EB

GiB 36-10.4EB  GiB 60-50GC

GiB 60-50GC  GiB 48-150GC

GiB 48-150GC  GiB 12-200

GiB 12-200  GiB 12-50

GiB 12-50  GiB 12-100

GiB 12-100  GiB 51R200

GiB 51R200  GiB 51R150

GiB 51R150  GiB 46.8-20EB

GiB 46.8-20EB  GiB 24-100

GiB 24-100  GiB 24-200

GiB 24-200  GiB 12-20MS

GiB 12-20MS  GiB 12-4MS

GiB 12-4MS  GiB 18-5.4DE

GiB 18-5.4DE  GiB 14.4-6.7OC

GiB 14.4-6.7OC  GiB 25.9-15XM

GiB 25.9-15XM  GiB 3.7-1.6HPC

GiB 3.7-1.6HPC  GiB 7.2-2.1SP

GiB 7.2-2.1SP  GiB 3.7-2.2SL

GiB 3.7-2.2SL  GiB 25.9-13SL

GiB 25.9-13SL  GiB 7.4-5.2EL

GiB 7.4-5.2EL  GiB 7.4-10SL

GiB 7.4-10SL  GiB 22.8-22FPV

GiB 22.8-22FPV  GiB 22.2-30FPV

GiB 22.2-30FPV  GiB 22.2-12FPV

GiB 22.2-12FPV  GiB 22.8-5FPV

GiB 22.8-5FPV  GiB 22.8-8FPV

GiB 22.8-8FPV  GiB 12-12SB

GiB 12-12SB  GiB 3.7-7.8RB

GiB 3.7-7.8RB  GiB 12-12SB

GiB 12-12SB  GiB 14.8-18RB

GiB 14.8-18RB  GiB 3.7-10PB

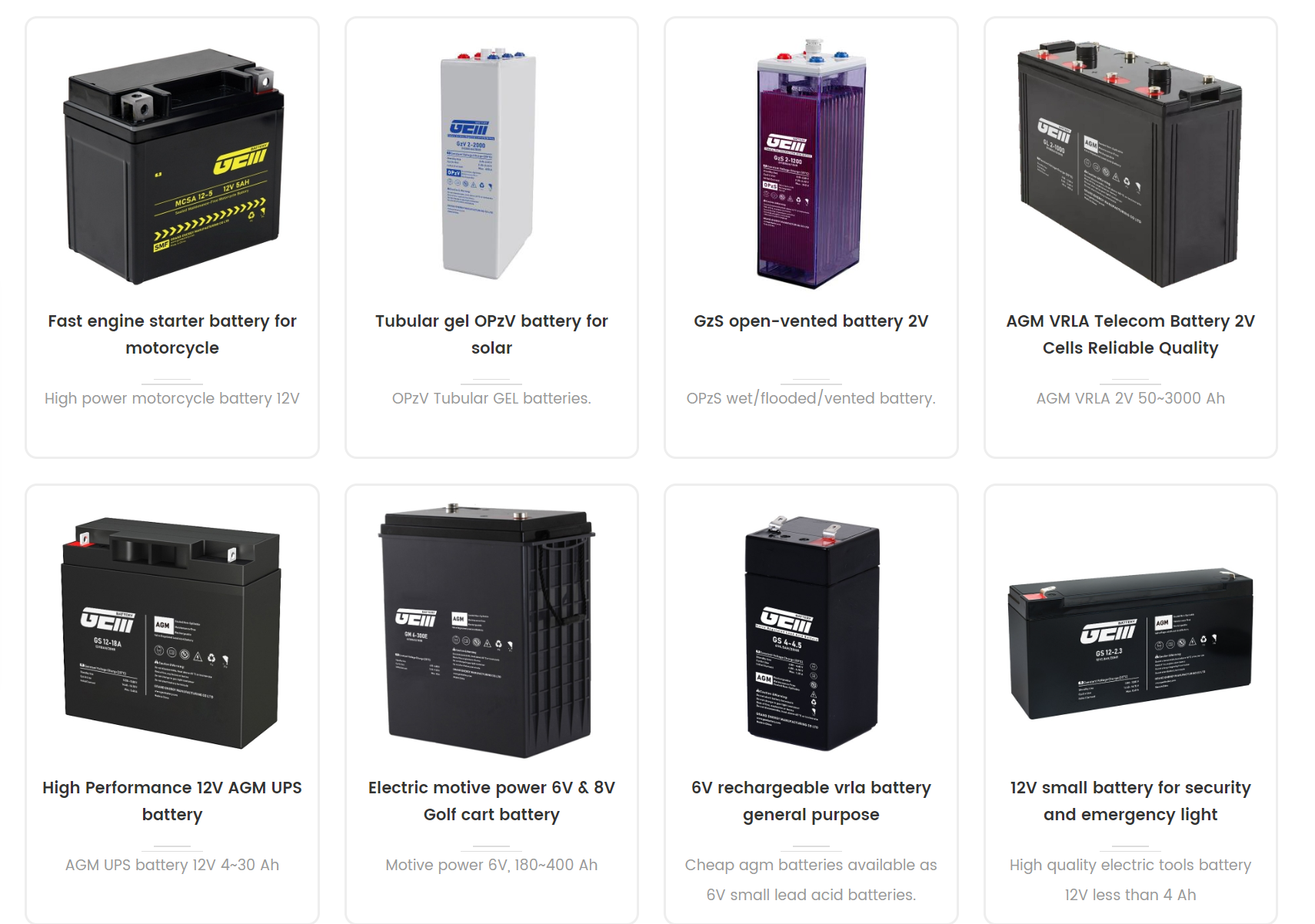

GiB 3.7-10PB  Lead-acid Battery | OPzV & OPz...

Lead-acid Battery | OPzV & OPz...