GEMFG AGV Lithium Batteries: Powering the Future of Intelligent Logistics and Automation

Date: 2024-05-04 Categories: Articles Hits: 1058

In the rapidly evolving landscape of industrial automation and intelligent logistics, AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) have become indispensable for modern manufacturing, warehousing, and distribution operations. These systems rely fundamentally on a continuous and stable power supply, making the lithium battery the core component that determines their operational efficiency and reliability. GEMFG specializes in the design and production of high-performance lithium battery solutions tailored specifically for AGV and AMR applications. Our batteries are engineered to deliver superior energy density, extended cycle life, and exceptional durability under demanding operational conditions, establishing a new benchmark for power sources in automated material handling and logistic systems.

The operational demands placed on AGV and AMR fleets within high-intensity warehouse and manufacturing environments are exceptionally rigorous. These robotic systems are required to perform around the clock with minimal downtime, which necessitates a battery solution that not only offers long power endurance but also maintains stability under varying loads and operating conditions. Any interruption in power can lead to significant disruptions in production schedules and logistic flows, underscoring the critical importance of a robust lithium battery system. Furthermore, the battery must support high-frequency charging and discharging cycles while providing consistent voltage output, ensuring that the AGV or AMR operates smoothly and predictably without unexpected shutdowns.

GEMFG’s AGV lithium batteries utilize advanced LiFePO4 chemistry, which is renowned for its thermal stability, safety, and long service life. This technology is particularly suited for high-throughput warehousing and logistic applications where reliability cannot be compromised. The high energy density of our lithium battery units allows for extended operation between charges, enabling AGVs and AMRs to complete extended shifts without frequent interruptions for recharging. Moreover, the stable discharge voltage curve of LiFePO4 cells helps maintain optimal performance of the vehicle’s drive and navigation systems, contributing to greater accuracy and efficiency in material transport and storage operations.

Another pivotal advantage of GEMFG’s lithium battery solutions is their exceptional performance across a wide temperature range. Industrial environments such as large-scale warehouse facilities or manufacturing plants often experience fluctuating temperatures, which can adversely affect battery performance and lifespan. Our AGV batteries are designed with integrated thermal management systems that ensure reliable operation even in challenging conditions. This capability minimizes power degradation and preserves energy availability, allowing AGVs and AMRs to perform consistently whether in refrigerated storage areas or high-temperature industrial zones.

Charging efficiency is also a crucial consideration in automated logistic systems. GEMFG’s lithium battery products support fast-charging capabilities that significantly reduce downtime, enabling rapid energy replenishment during short breaks or scheduled pauses. This feature is especially valuable in high-utilization settings where maximum equipment availability is essential. With advanced battery management systems (BMS) that monitor and regulate charging parameters, our batteries achieve optimal recharge cycles without compromising safety or longevity, thereby enhancing overall productivity in warehousing and distribution operations.

Safety is of paramount importance in environments where humans and machines collaborate. GEMFG’s AGV lithium batteries are equipped with comprehensive protection mechanisms that include overcharge prevention, over-discharge control, short-circuit protection, and temperature monitoring. These features ensure operational safety and mitigate risks such as thermal runaway or energy failure. The use of LiFePO4 chemistry further enhances safety due to its inherent resistance to high temperatures and structural stability, making it an ideal power source for automated systems operating in dynamic and people-populated settings.

The application of GEMFG’s lithium battery technology spans a diverse spectrum of industrial and logistic scenarios. In large-scale warehouse operations, for instance, our batteries provide the endurance and reliability required for continuous goods movement, sorting, and storage. In manufacturing facilities, they power AGVs that supply production lines with components and materials, ensuring seamless workflow and just-in-time delivery. Furthermore, in e-commerce fulfillment centers and distribution hubs, GEMFG battery systems enable AMRs and AGVs to operate with high precision and energy economy, supporting the ever-growing demands of modern supply chains.

GEMFG is committed to delivering lithium battery solutions that meet the highest standards of quality and performance. Every battery undergoes stringent testing and validation under real-world conditions, ensuring that it meets the rigorous demands of AGV and AMR applications. Our dedicated technical support team provides comprehensive services, including system integration guidance, maintenance advice, and timely troubleshooting, ensuring that customers achieve optimal performance and maximum return on investment throughout the battery lifecycle.

By integrating cutting-edge LiFePO4 technology with innovative power management design, GEMFG empowers the future of automation and smart logistic operations. Our lithium batteries are not merely energy sources; they are enablers of efficiency, safety, and sustainability in the rapidly advancing field of industrial EV and robotic applications.

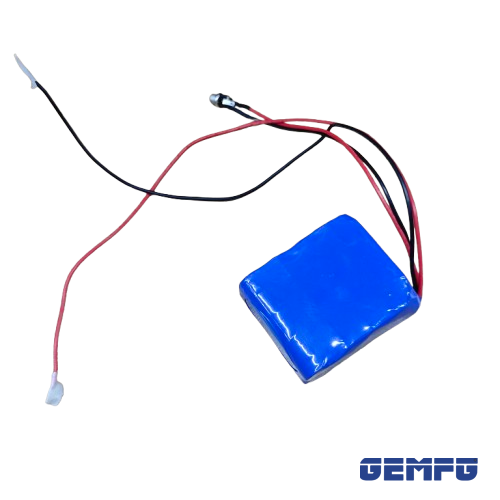

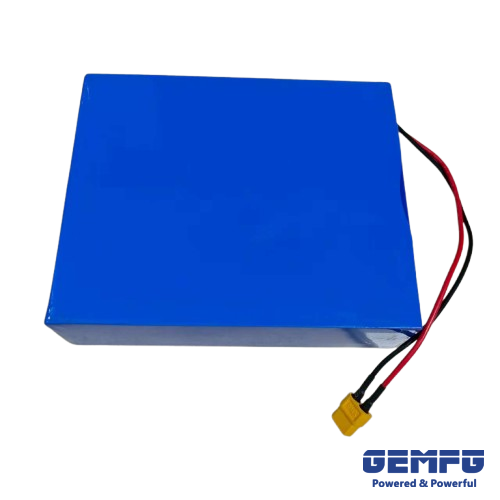

GiB 25.2-2VB

GiB 25.2-2VB  GiB 25.2-12.4EB

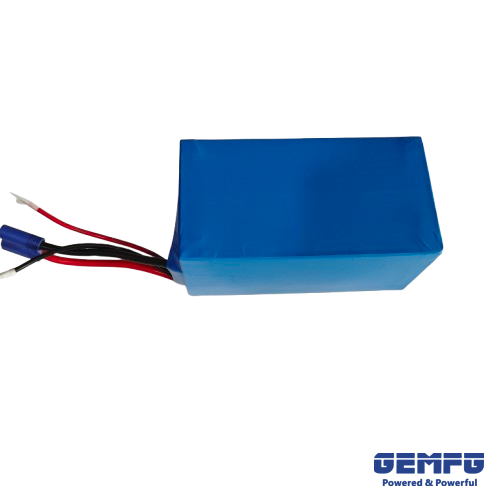

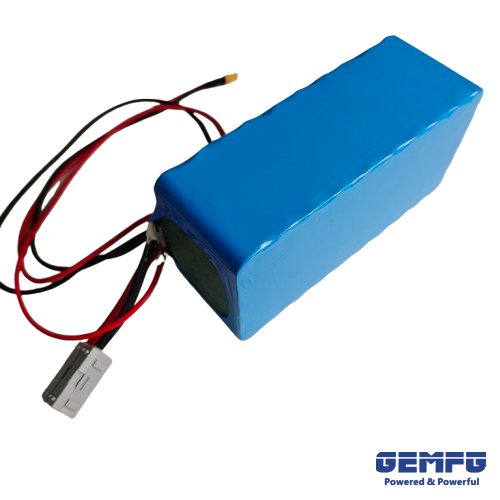

GiB 25.2-12.4EB  GiB 12-3SB

GiB 12-3SB  GiB 46.8-20EB

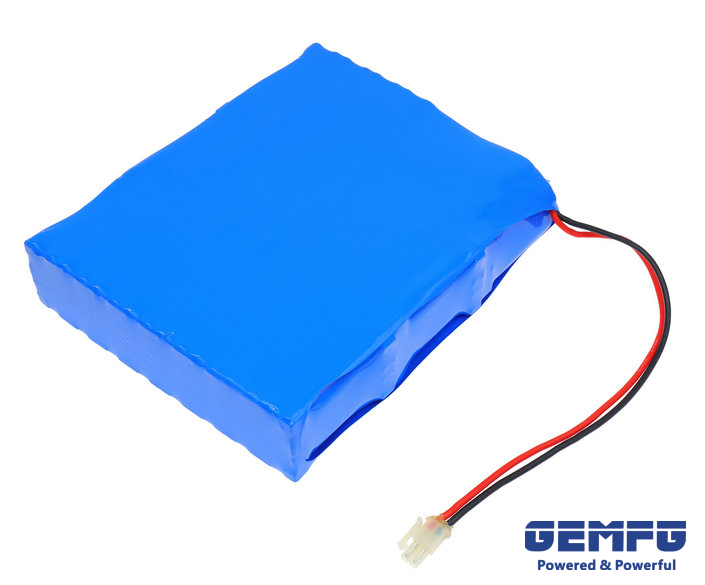

GiB 46.8-20EB  GiB 24-16RB

GiB 24-16RB  GiB 12-200

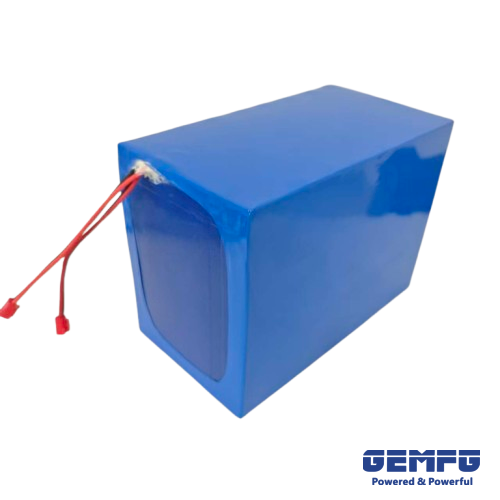

GiB 12-200  GiB 12-50

GiB 12-50  GiB 12-100

GiB 12-100  GiB 51R200

GiB 51R200  GiB 51R150

GiB 51R150  GiB 12.8-18GT

GiB 12.8-18GT  GiB 12-6SMB

GiB 12-6SMB  GiB 12-15ES

GiB 12-15ES  GiB 24-100

GiB 24-100  GiB 24-200

GiB 24-200  GiB 12-20MS

GiB 12-20MS  GiB 12-4MS

GiB 12-4MS  GiB 18-5.4DE

GiB 18-5.4DE  GiB 14.4-6.7OC

GiB 14.4-6.7OC  GiB 25.9-15XM

GiB 25.9-15XM  GiB 3.7-1.6HPC

GiB 3.7-1.6HPC  GiB 7.2-2.1SP

GiB 7.2-2.1SP  GiB 12-138SL

GiB 12-138SL  GiB 12-36SL

GiB 12-36SL  GiB 12-20SL

GiB 12-20SL  GiB 3.7-2.2SL

GiB 3.7-2.2SL  GiB 25.9-13SL

GiB 25.9-13SL  GiB 22.8-22FPV

GiB 22.8-22FPV  GiB 22.2-30FPV

GiB 22.2-30FPV  GiB 22.2-12FPV

GiB 22.2-12FPV  GiB 22.8-5FPV

GiB 22.8-5FPV  GiB 22.8-8FPV

GiB 22.8-8FPV  GiB 36-10.4RB

GiB 36-10.4RB  GiB 36-15SB

GiB 36-15SB  GiB 48-2PT

GiB 48-2PT  GiB 3.7-7.8RB

GiB 3.7-7.8RB  GiB 14.8-18RB

GiB 14.8-18RB  GiB 12-6SB

GiB 12-6SB  GiB 12-12SB

GiB 12-12SB  GiB 12-12SB

GiB 12-12SB  Lead-acid Battery | OPzV & OPz...

Lead-acid Battery | OPzV & OPz...