GEMFG AGV Lithium Batteries: Powering the Future of Intelligent Logistics and Automated Warehousing

Date: 2021-06-05 Categories: Articles Hits: 1096

In contemporary industrial ecosystems, the seamless operation of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) is fundamental to the efficiency of modern logistics and warehousing operations. These robotic workhorses form the backbone of material handling in distribution centers, manufacturing plants, and large-scale storage facilities, where their uninterrupted performance is critical for maintaining supply chain velocity. The core component enabling this continuous, reliable operation is the AGV lithium battery, which serves as the essential power source for these automated systems. GEMFG AGV lithium batteries are engineered to meet the rigorous demands of industrial automation, providing the exceptional endurance, reliability, and intelligence required for 24/7 operation. Our advanced lithium battery technology delivers superior performance compared to traditional power sources, establishing a new benchmark for powering the material handling equipment that drives the future of intralogistics.

The operational integrity of an entire logistics or warehousing facility can be contingent upon the consistent performance of its AGV and AMR fleet. Any interruption in power, whether due to insufficient capacity, lengthy charging cycles, or battery failure, can cause significant bottlenecks, leading to delayed order fulfillment, disrupted production lines, and substantial financial losses. Therefore, the power solution for these automated systems must fulfill a stringent set of requirements. Primarily, the lithium battery must offer an extended operational runtime, enabling AGVs and AMRs to complete extended shifts without frequent and time-consuming interruptions for charging. This exceptional endurance must be coupled with unwavering reliability, allowing the battery to perform consistently under challenging conditions such as constant vibration, fluctuating temperatures within warehouses, and exposure to dust. Furthermore, the ability to recharge rapidly is non-negotiable; AGV lithium battery systems must support opportunity charging during short breaks or even wireless inductive charging to maximize equipment uptime and overall facility productivity.

GEMFG AGV lithium batteries are meticulously designed with these critical demands in mind, featuring ultra-long endurance that guarantees uninterrupted operation throughout extended and demanding work cycles. By utilizing advanced high-density lithium cells and a proprietary electrode formulation, we significantly enhance the energy storage capacity of our battery units. This advanced engineering allows a single GEMFG lithium battery to power a standard AGV or AMR for multiple full shifts, effectively supporting intensive logistics operations without performance degradation. This extended capability is further augmented by an optimized internal circuit design that minimizes self-discharge rates, ensuring that the stored energy is available precisely when needed. Whether deployed in a compact AMR for light-item transport or a heavy-duty AGV for pallet movement in high-bay warehousing, our lithium battery solutions provide the dependable, long-lasting power required to keep automated material handling systems running smoothly and efficiently, thereby safeguarding productivity across the entire logistics chain.

Recognizing that AGV and AMR operations are conducted in diverse and often harsh industrial environments, GEMFG lithium batteries are built for superior stability and reliability. We employ specialized sealing technologies and robust protective housing materials to create a battery that is highly resistant to ingress from dust, moisture, and humidity, which are common in warehousing and manufacturing settings. This robust construction ensures that the lithium battery remains fully operational even in less-than-ideal conditions, from dusty warehouse aisles to damp storage areas. Moreover, our AGV lithium battery products are engineered with a sophisticated thermal management system, granting them exceptional tolerance to temperature variations. They deliver consistent and reliable power output and charging performance even when subjected to the elevated temperatures found in industrial facilities or the lower temperatures of cold storage logistics environments, ensuring that the AGV fleet remains operational regardless of external factors.

A defining feature of the GEMFG AGV lithium battery is its rapid recharge capability, a critical attribute for maximizing the utilization of valuable AGV and AMR assets. Our batteries incorporate intelligent charging algorithms that dynamically adjust charging parameters based on the battery's real-time status. This advanced technology dramatically reduces downtime by enabling rapid opportunity charging during short scheduled breaks or shift changes, ensuring that the lithium battery is quickly restored to a high state of charge and ready for the next assignment. This fast-charge capability is a cornerstone for operations aiming to implement continuous, multi-shift logistics and warehousing workflows, as it directly translates to higher equipment availability, greater throughput, and a significantly improved return on investment for automated material handling systems.

Within the context of industrial automation, safety is the foremost priority. GEMFG integrates a comprehensive multi-layered protection system into every AGV lithium battery we manufacture. This integrated Battery Management System (BMS) provides continuous monitoring and active protection against a wide spectrum of potential fault conditions, including overcharge, over-discharge, overcurrent, short-circuit, and thermal runaway. The BMS acts as an intelligent guardian, instantly intervening to mitigate risks and prevent hazardous situations, thereby ensuring the absolute safety of both the robotic equipment and the personnel working alongside it. The lithium battery cells are further housed within enclosures constructed from premium fire-retardant materials, adding an extra layer of passive safety and ensuring compliance with the most stringent international safety standards for industrial battery applications.

The application scope for GEMFG AGV lithium batteries is vast and covers the entire spectrum of automated material handling. In e-commerce fulfillment centers and distribution hubs, our high-capacity lithium battery solutions empower AGV and AMR fleets to manage endless waves of orders with relentless efficiency, directly enhancing logistics performance. Within manufacturing plants, they provide the dependable power needed for production line feeding and parts transportation, supporting just-in-time manufacturing processes. For warehousing operations, including high-bay storage and retrieval systems, the reliability and long life of our battery products reduce the total cost of ownership and minimize maintenance interventions. Furthermore, our lithium battery technology is perfectly suited for powering the next generation of AMRs that collaborate safely with human workers, enabling flexible and scalable automation across various logistics scenarios.

GEMFG is unwaveringly committed to advancing the field of industrial energy solutions. Our AGV lithium batteries are produced under a rigorous quality management system, with every production stage—from raw material selection and cell manufacturing to final assembly and testing—subjected to meticulous control to ensure unparalleled quality and performance. We complement our superior products with comprehensive technical support and customer service, providing expert guidance on battery integration, optimization, and maintenance. This end-to-end commitment ensures that our clients in the logistics, warehousing, and manufacturing sectors can deploy our lithium battery technology with complete confidence, empowering their automated operations and driving the future of intelligent industrial automation forward.

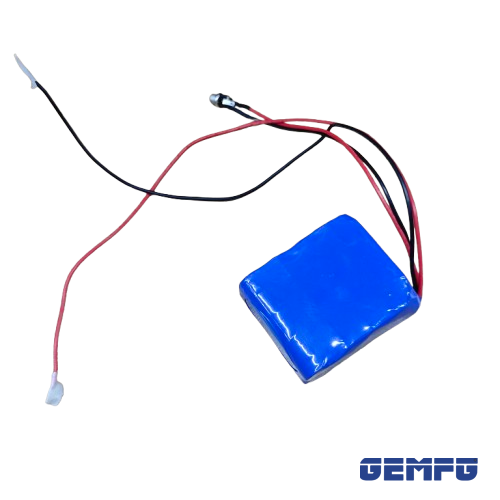

GiB 25.2-2VB

GiB 25.2-2VB  GiB 25.2-12.4EB

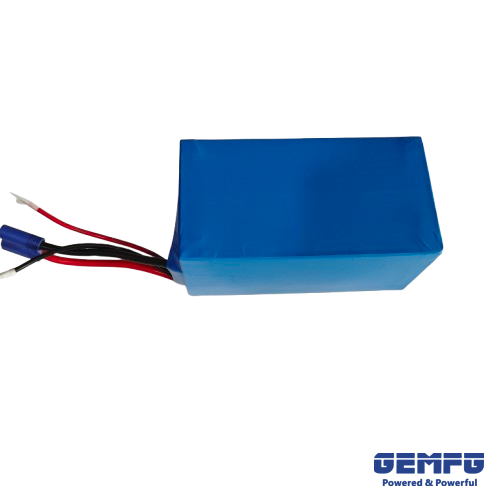

GiB 25.2-12.4EB  GiB 12-3SB

GiB 12-3SB  GiB 46.8-20EB

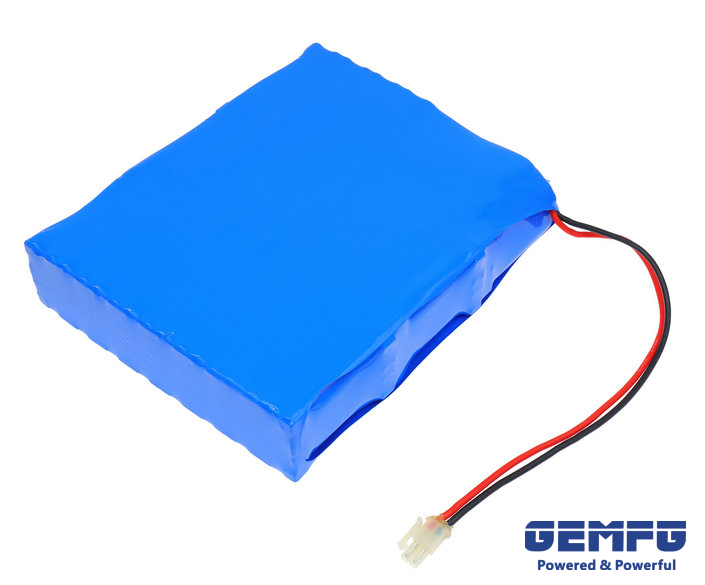

GiB 46.8-20EB  GiB 24-16RB

GiB 24-16RB  GiB 12-200

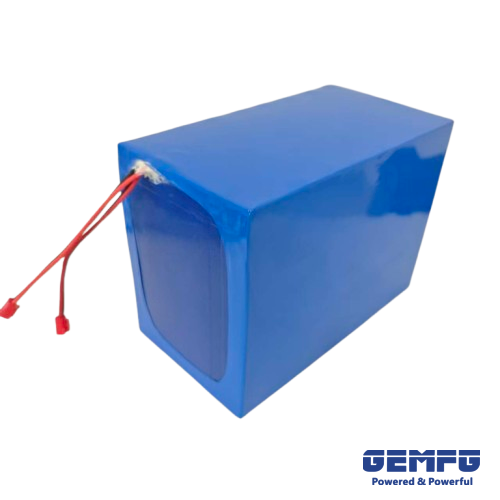

GiB 12-200  GiB 12-50

GiB 12-50  GiB 12-100

GiB 12-100  GiB 51R200

GiB 51R200  GiB 51R150

GiB 51R150  GiB 12.8-18GT

GiB 12.8-18GT  GiB 12-6SMB

GiB 12-6SMB  GiB 12-15ES

GiB 12-15ES  GiB 24-100

GiB 24-100  GiB 24-200

GiB 24-200  GiB 12-20MS

GiB 12-20MS  GiB 12-4MS

GiB 12-4MS  GiB 18-5.4DE

GiB 18-5.4DE  GiB 14.4-6.7OC

GiB 14.4-6.7OC  GiB 25.9-15XM

GiB 25.9-15XM  GiB 3.7-1.6HPC

GiB 3.7-1.6HPC  GiB 7.2-2.1SP

GiB 7.2-2.1SP  GiB 12-138SL

GiB 12-138SL  GiB 12-36SL

GiB 12-36SL  GiB 12-20SL

GiB 12-20SL  GiB 3.7-2.2SL

GiB 3.7-2.2SL  GiB 25.9-13SL

GiB 25.9-13SL  GiB 22.8-22FPV

GiB 22.8-22FPV  GiB 22.2-30FPV

GiB 22.2-30FPV  GiB 22.2-12FPV

GiB 22.2-12FPV  GiB 22.8-5FPV

GiB 22.8-5FPV  GiB 22.8-8FPV

GiB 22.8-8FPV  GiB 36-10.4RB

GiB 36-10.4RB  GiB 36-15SB

GiB 36-15SB  GiB 48-2PT

GiB 48-2PT  GiB 3.7-7.8RB

GiB 3.7-7.8RB  GiB 14.8-18RB

GiB 14.8-18RB  GiB 12-6SB

GiB 12-6SB  GiB 12-12SB

GiB 12-12SB  GiB 12-12SB

GiB 12-12SB  Lead-acid Battery | OPzV & OPz...

Lead-acid Battery | OPzV & OPz...